The Sunshine Extrusions pvt ltd

A Lead MANUFACTURER and SUPPLIER based in Tumkur.

The discovery and processing of metals on planet earth is a great innovation for the modern life of the humanity. Copper next to steel is a unique metal with its versatile properties when mixed with other metals and further followed by proper processing to create the metal for diverse applications, are indeed a fascination to all of us.

Since 1993, Sunshine Extrusions has worked hard to develop copper alloys which are being used at various applications, particularly to meet the sophisticated customers requirements and the quality to international standards. Through this Sunshine Extrusions is servicing this field to the utmost satisfaction of the customers in terms of quality, pricing and delivery.

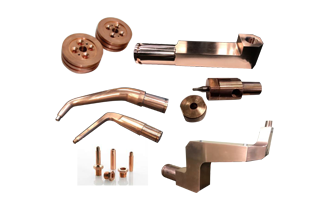

Resistance welding products

Resistance welding is used in the sheet metal fabrication industry for welding and joining applications. Sunshine manufactures the widely used consumables of spot welding cap tips, various electrodes, seam welding wheels and spare / machined parts like shanks, adaptors, holders and gun arms used for resistance welding.

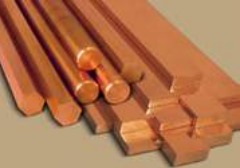

Rods

Alloys Offered

caps

Products

wheels,shanks,holders,adapters & short circuit rings

products

Automotive industry

For the last 10 years as a diversification to the earlier production for 18 years of brass manufacturing, company has developed through their R&D- manufacturing of resistance welding alloys of C18200, C18150 and C18000. We have a plant capacity of around 250 tons per month of raw material manufacturing. Since the above raw material consumption on pan India is very low, we have developed consumables and maintenance parts for automotive industries used in resistance welding particularly catering to welding involved in sheet metal with high technologies like robot welding.

Automotive products

Alloys Offered

railways

Alloys Offered

steel industry

Products

Our Vision

Sunshine Extrusions pledges to service the global market for various sophisticated copper alloys through welldefined technical processes and high standard of quality with competitive prices.

our production infrastructure

Sunshine strives to be equipped with the latest technology for manufacturing and quality assurance. With heavy duty metal furnaces of varying capacities and higher capacity extrusion press, we are capable of meeting a variety of customers requirements with high quality and quick delivery times. Quality is our topmost priority and hence we have invested substantially on quality assurance equipment which coupled with the ISO 9001:2008 quality system to ensure complete customer satisfaction.

Sunshine also has a completely equipped machine shop with CNC turning and Milling machines to add value to its raw material into precision machine products

our process flow

Raw materials

Extruding

Melting

Pointing

Casting

Drawing

Billet Cutting

Process Annealing

Billet Heating

Drawing

Straitening

Eddy Current Testing

Cutting

Final Inspection

mechanical properties physical properties visual insfection

Packeging

Contact us

Get in touch

We support our customers with more than 50 years of expertise

FACTORY ADDRESS : 38/ F Hirehalli Industrial area

Tumkur- 572168, Karnataka, India.

Email: info@sunshineextrusions.com

Website: www.sunshineextrusions.com

Phone: +91- 816- 224341